Author/Contributor: ENBIX, Beyond Code, Performance Haus

We’ve heard from representatives from Alberta’s building industry about the challenges of keeping projects affordable while improving home airtightness and enhancing occupant comfort. They have also expressed challenges in training tradespeople on new technologies specific to our climate zones.

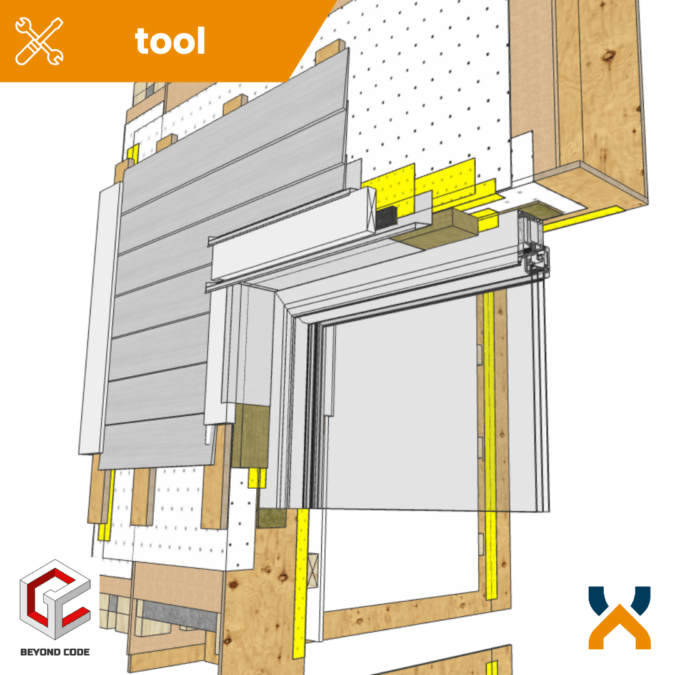

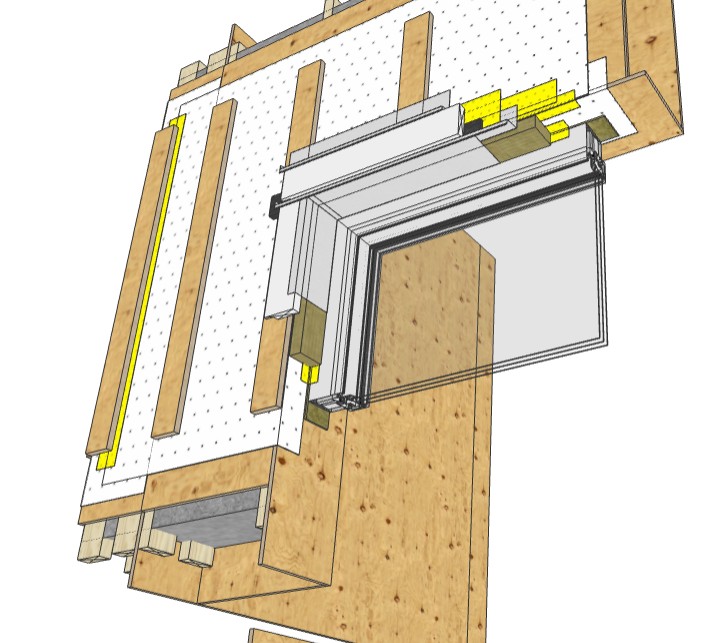

To help address these issues, Alberta Ecotrust Foundation, through the ENBIX initiative, has worked with Beyond Code (with funding from the Peter Gilgan Foundation) in developing 3D models of high-performance residential building envelope assemblies.

These models show different assembly options and methods for building cost-effective, energy-efficient homes made for Alberta. The project goal is to support builders, designers, and homeowners, whether you’re aiming to construct a new net-zero home, retrofit existing homes for better thermal performance, or understand how the components of a building envelope work together.

These 3D models allow trades to see specific details for the building envelope, from multiple views. These models can viewed on the job site using low-cost technologies such as tablets. The designs can be commissioned from Beyond Code to show a builder’s preferred building envelope design and methods. This creates another tool to supplement training for trades that goes beyond the traditional limitations of architectural plans and details. It also allows for revisions to be made to the models when mistakes are found rather than making those mistakes on-site, costing time, money, and wasted materials.

Getting started guide to the 3D models:

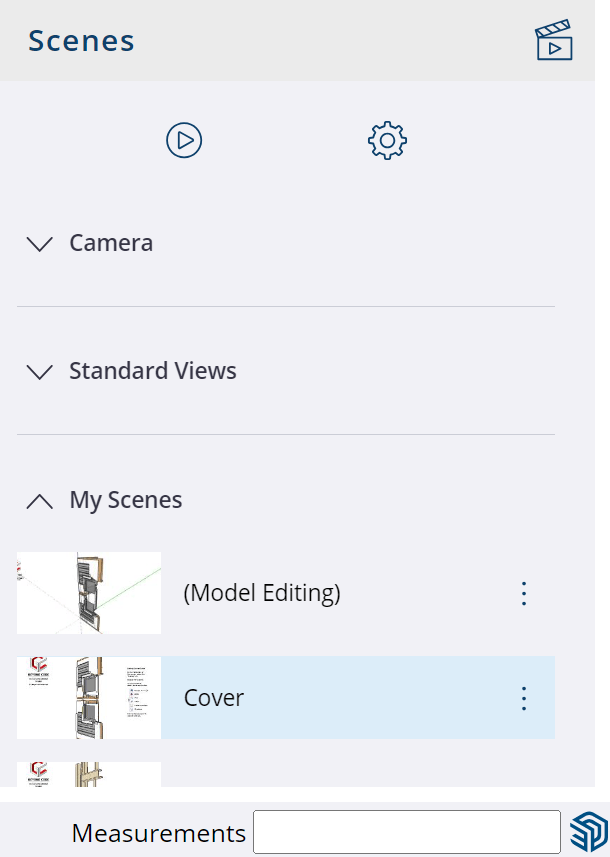

The navigation menu is on the edge of the screen. If viewing on a laptop, to pan, hold the shift key, click and drag. Drag the model to orbit around, and use the mouse wheel to zoom in and out.

The menu is on the right edge of the screen. To watch the animation in order of construction, select the “Scenes” tab. The play button on the left will start the animation. The settings cog on the right lets you change the transition and delay time between animations. You can also click on any of the individual scenes under “my scenes” and see that detail.

Check it out on any of the models below. Click on the underlined links for specific 3D model details.

New Construction:

High-Performance: Poly Core Assembly

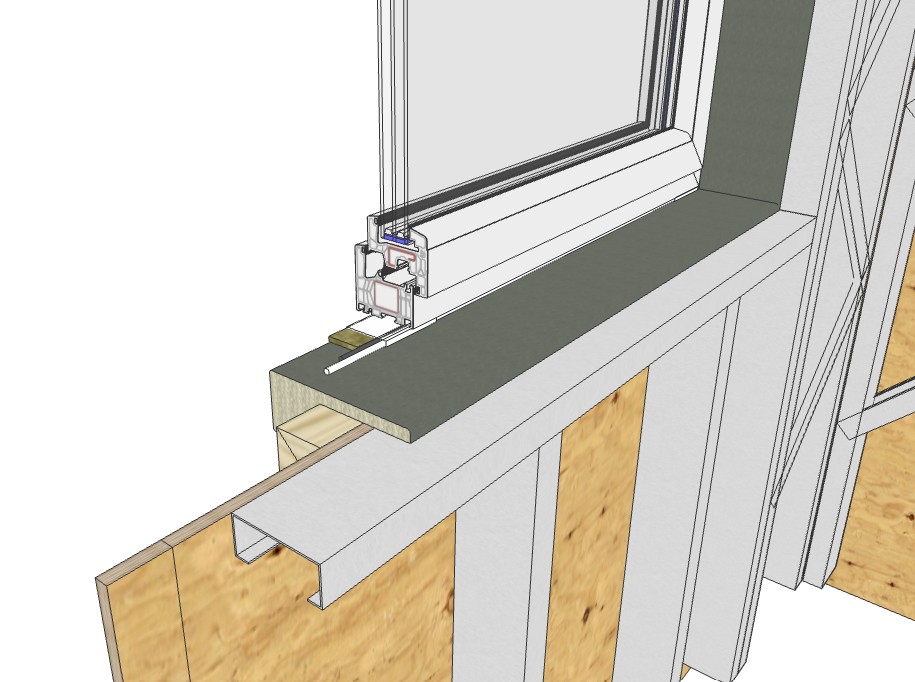

- Window Detail

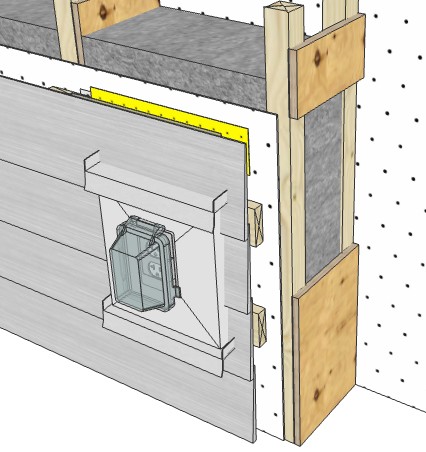

- Exterior Wall – Electrical Penetration Detail

- Exterior Wall – Duct Penetration Detail

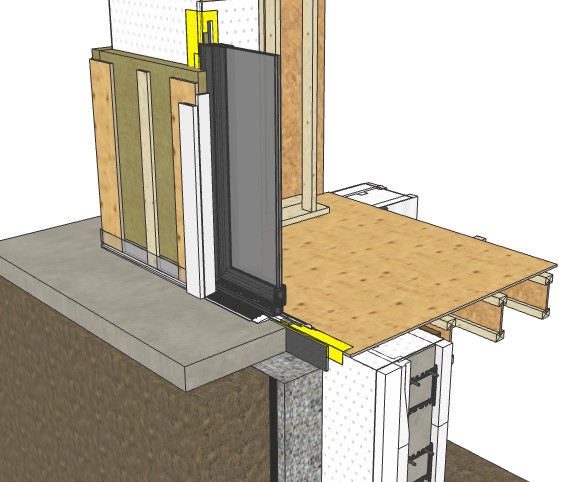

- Foundation Detail

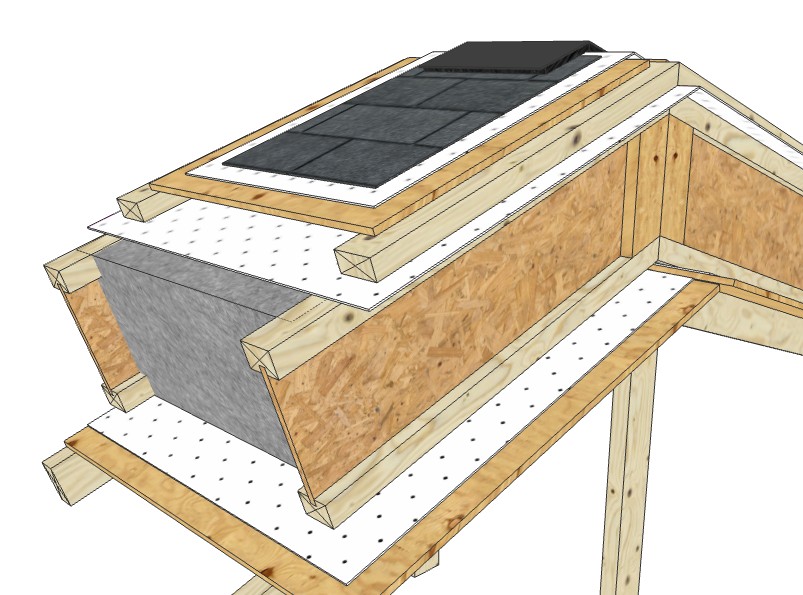

- Roof Detail

U-Values and more data can be found here.

Net Zero: Double Stud Assembly

- Window Detail

- Exterior Wall – Electrical Penetration Detail

- Exterior Wall – Duct Penetration Detail

- Slab On Grade Detail

- Roof Detail

U-Values and more data can be found here.

Net Zero: Steel Stud Exterior Insulation Assembly

- Window Detail

- Exterior Wall – Electrical Penetration Detail

- Exterior Wall – Duct Penetration Detail

- Foundation Detail

- Roof Detail

U-Values and more data can be found here.

For comparison to new construction:

Passive House Assembly

A super-insulated Passive House assembly. Passive houses require high levels of insulation, sometimes referred to as super insulation, to achieve a U-value between 0.08 W/m2K to 0.15 W/m2K. Typical walls might be 12″ to 24″ thick (R35 to R60) and roofs might be 18″ to 36″ thick (R50 to R100) for Passive House construction.

- Ground Floor Door Above Crawlspace Detail

- Exterior Wall – Electrical Penetration Detail

- Exterior Wall – Duct Penetration Detail

- Vented Roof Detail

U-Values and more data can be found here.

Business-as-usual Assembly

What the City of Edmonton and Calgary are most commonly seeing in residential construction in 2024:

- Window Detail

- Exterior Wall – Electrical Penetration Detail

- Exterior Wall – Duct Penetration Detail

- Foundation / Conditioned Crawl Space Detail

- Roof Detail

U-Values and more data can be found here.

Retrofits:

High-Performance: Retrofit Assembly

- Window Detail

- Exterior Wall – Electrical Penetration Detail

- Exterior Wall – Duct Penetration Detail

- Foundation Detail

- Roof Detail

U-Values and more data can be found here.

Net Zero: Retrofit Assembly

- Window Detail

- Exterior Wall – Electrical Penetration Detail

- Exterior Wall – Duct Penetration Detail

- Foundation Detail

- Roof Detail

U-Values and more data can be found here.

Summary:

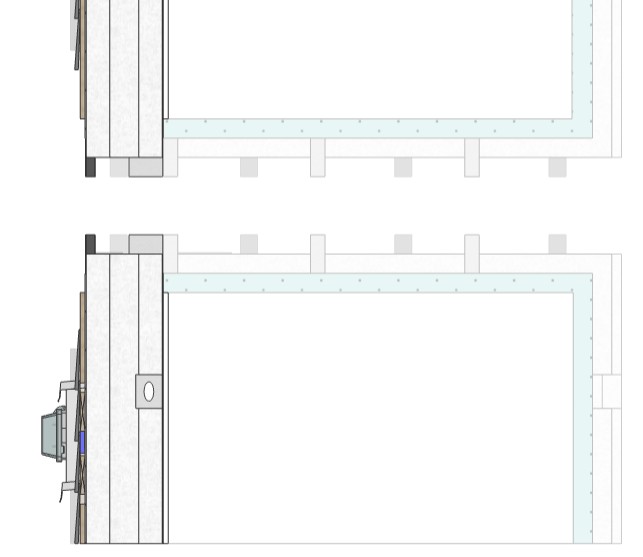

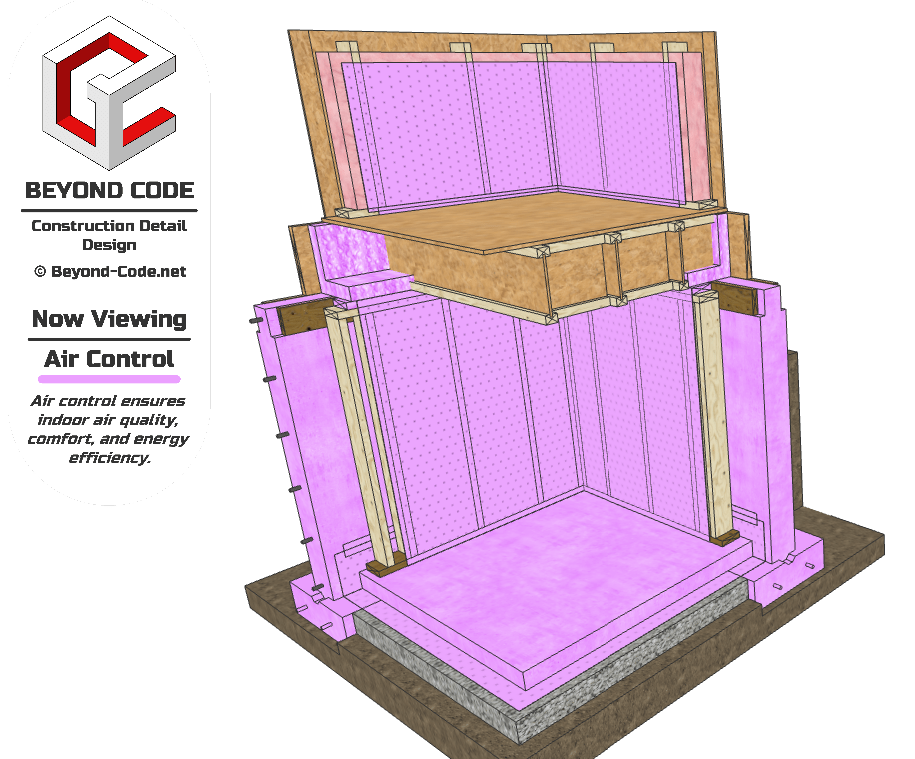

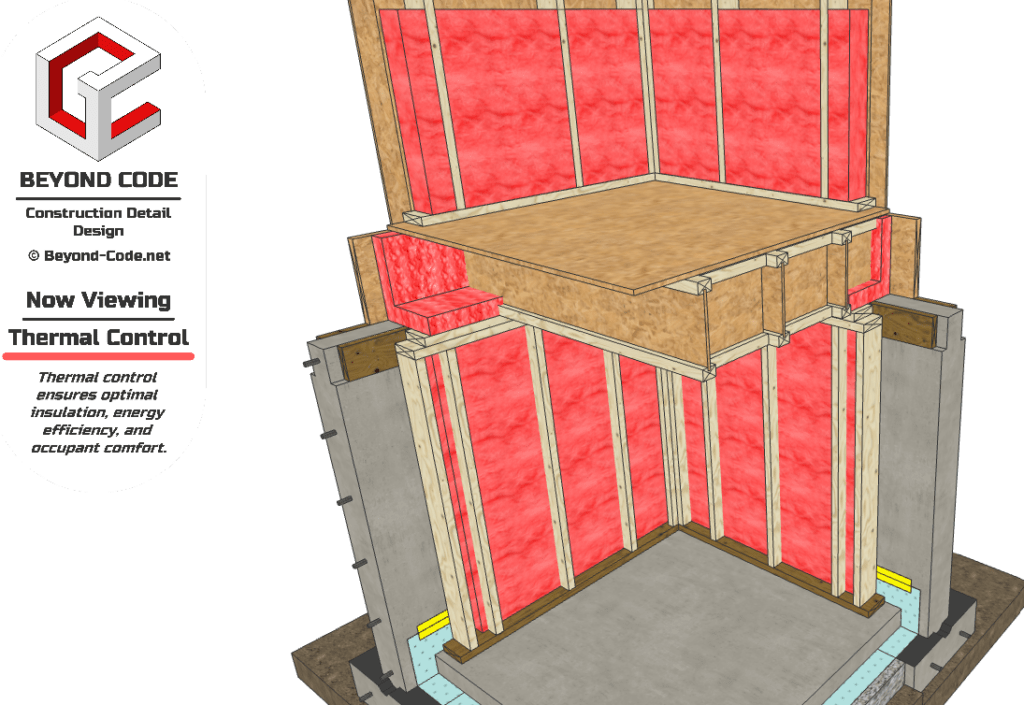

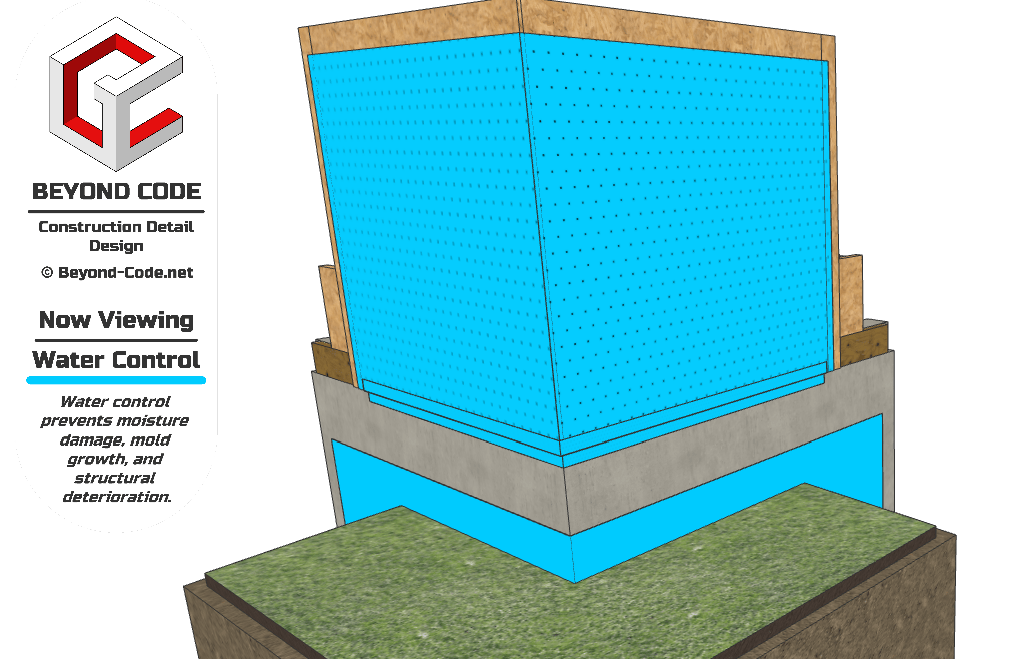

The 3D models include the control layers (at the bottom of scenes) that highlight the materials of the building envelope that apply to each. The control layers to address when you are trying to attain higher levels of energy performance are:

- Air

- Thermal

- Water

- Vapour

Air control layers are achieved through an air barrier material that is continuous. Air control materials can be: sheet materials (plywood, OSB), fluid and self-applied membranes, or are mechanically fastened.

The thermal control layer is the insulation and is often referred to as the building’s blanket. To see the U-values of the assemblies, you can find the datasheet here.

The water control layer is important to keep rain, snow, and sleet from damaging the wood sheathing and frame within the building envelope. This layer includes items such as rain screens to promote drainage. To help prevent water from damaging further, properly installed and sequenced weather-resistant barriers, flashing, and drainage are all crucial components of this layer.

Vapour is moisture when it’s airborne and it can infiltrate into building envelopes and cause damage. If vapour becomes trapped inside an assembly, it can condense and turn into a liquid, which will mold. The vapour control layer mitigates this by controlling the movement of water vapor through the building envelope. Poly vapour barriers or self-adhered underlayments are the most common.

Looking ahead, ENBIX will be expanding on this work with more high-performance building envelope assembly content in the coming months. This will include physical wall assembly mockups and presentations at BuildEX and the Canmore Building for Sustainability conferences. Stay tuned to enbix.ca/resources and subscribe to our newsletter for these updates and more resources to help you build more efficiently.

The design, plans, information, and content (the “Content”) as provided for on this site by Beyond Code, and on behalf Alberta Ecotrust Foundation (herein “Alberta Ecotrust”) are for demonstration and informational purposes only. The Content should be reviewed and vetted by the user’s own professionals and advisors in order to ensure the applicability and suitability of any of the Content to the user’s own project or plans before making use of same, and the user acknowledges they do so at their own risk at all times. The user also acknowledges and agrees that Alberta Ecotrust is not responsible for the accuracy, applicability, and/or viability of the Content as presented anywhere herein, and that Alberta Ecotrust shall not be liable for the user’s use of any of the Content as presented herein, as the Content is for informational purposes only, and has not been prepared specifically for the user.